Cold Mix Asphalt: The Eco-Friendly Option for Long-lasting Roads

Cold mix asphalt has actually arised as a sensible alternative for eco-conscious roadway building projects, offering an array of benefits that cater to both sustainability and effectiveness. By incorporating recycled products, lowering waste, and promoting lower energy consumption during production, cool mix asphalt lines up with ecological requirements while guaranteeing resilient roadway surface areas.

Advantages of Cold Mix Asphalt

Cold mix asphalt uses a affordable and ecologically lasting option for roadway building and upkeep. One key benefit of cold mix asphalt is its versatility. Unlike warm mix asphalt, which requires heats during laying and blending, chilly mix asphalt can be utilized in lower temperatures, making it ideal for winter conditions or emergency fixings. This flexibility allows for year-round road maintenance and building tasks, minimizing downtime and making certain smoother traffic flow (cold mix asphalt).

An additional advantage of cold mix asphalt is its convenience of application. Because it can be stockpiled and utilized as required without the demand for heating equipment, it streamlines the building and construction process and lowers energy usage. Additionally, cool mix asphalt is more flexible throughout application, permitting longer workability and less complicated compaction contrasted to hot mix asphalt.

In addition, chilly mix asphalt provides exceptional longevity and resistance to water penetration, causing longer-lasting roadway surfaces. Its ability to abide by existing pavement surface areas makes it a preferred choice for pit repair services and sidewalk conservation jobs. On the whole, the benefits of chilly mix asphalt make it a functional and reliable solution for lasting road facilities advancement.

Environmental Benefits

With an emphasis on sustainability and eco-friendliness, the environmental benefits of using chilly mix asphalt in roadway building and maintenance are considerable. Cold mix asphalt manufacturing calls for reduced temperature levels contrasted to hot mix asphalt, resulting in lowered energy usage and reduced greenhouse gas exhausts. Additionally, cold mix asphalt is usually produced utilizing recycled materials such as redeemed asphalt sidewalk (RAP) and recycled asphalt roof shingles (RAS)

Easy Application and Upkeep

Efficient application and maintenance treatments play a critical function in the successful application of cool mix asphalt for road building and construction projects. Cold mix asphalt provides a considerable benefit in regards to very easy application contrasted to warm mix asphalt. Given that cool mix asphalt does not call for heating during the blending procedure, it can be stocked and applied at ambient temperature levels. This streamlines the application procedure, decreasing the energy consumption and discharges connected with standard warm mix asphalt manufacturing.

Maintenance of roadways constructed with cold mix asphalt is likewise much more uncomplicated. Cold mix asphalt has improved versatility and sturdiness, allowing it to stand up to fluctuations in temperature and rush hour lots without splitting as easily as conventional hot mix asphalt. When maintenance is needed, cool mix asphalt can be quickly reapplied to harmed areas without the requirement for extensive prep work or specialized equipment. This ease of maintenance aids extend the life-span of roads, decreasing general upkeep prices and decreasing interruptions to web traffic flow. On the whole, the easy application and upkeep of chilly mix asphalt make it a sustainable and functional selection for resilient road building and construction tasks.

Cost-Effectiveness in Roadway Construction

Cost-effectiveness is an essential factor to consider in the planning and implementation of road building projects, influencing budget allocations and lasting sustainability goals. Cold mix asphalt supplies a cost-effective option for road building as a result of its lower production and application costs compared to warm mix asphalt. The decreased power intake in the production process adds to overall expense financial savings, making it an eye-catching option for various roadway jobs.

Moreover, the convenience of application and upkeep of cold mix asphalt better boosts its cost-effectiveness. With cool mix asphalt, road building and construction jobs can be completed faster, resulting in minimized labor expenses and minimized disruptions to web traffic flow. Additionally, the ability to store cool mix asphalt for extended periods without endangering its quality permits mass purchasing, causing possible discount rates and general price savings.

Toughness and Long Life

Guaranteeing the durability and resilience of roadway framework is a basic aspect of sustainable construction practices. When considering road building and construction materials, durability plays a crucial duty in determining the lifespan of the road. Cold mix asphalt, known for its long life, provides a sustainable option for resilient roadways. Its one-of-a-kind make-up enables for adaptability, enabling it to withstand differing weather condition conditions and rush hour loads with time.

One key element adding to the sturdiness of cool mix asphalt is its ability to withstand breaking. Conventional warm mix asphalt is prone to breaking as a result of temperature changes, while cold mix asphalt preserves its architectural honesty, minimizing try this web-site the need for regular repair work. This longevity causes price financial savings and minimizes the environmental influence related to roadway maintenance activities.

Additionally, the long life site here of cold mix asphalt extends the life-span of roadways, lowering the regularity of reconstruction jobs. By choosing materials that prioritize durability, such as cool mix asphalt, road framework can be developed to last, advertising sustainability and effective resource utilization in the building sector.

Conclusion

Finally, cool mix asphalt uses a lasting and environment-friendly solution for constructing long-lasting roadways. Its benefits consist of adaptability in numerous climate conditions, streamlined building process, and outstanding toughness. With reduced production temperatures, usage of recycled materials, and minimized waste generation, it promotes environmental advantages. Easy upkeep, application, and cost-effectiveness even more enhance its appeal, adding to prolonged road life expectancies and reliable resource use according to sustainability goals.

Unlike hot mix asphalt, which requires high temperatures during laying and mixing, cold mix asphalt can be made use of in lower temperatures, making it perfect for cold weather conditions or emergency situation repair work - asphalt patch repair. Cold mix asphalt production calls for lower temperatures compared to warm mix asphalt, resulting in reduced power usage and lower greenhouse gas exhausts. Cold mix asphalt provides a significant advantage in terms of easy application contrasted to hot mix asphalt. Cold mix asphalt provides an affordable solution for roadway construction due to its reduced manufacturing and application expenses compared to hot mix asphalt. Traditional click over here now warm mix asphalt is vulnerable to splitting due to temperature variations, while chilly mix asphalt maintains its structural integrity, decreasing the requirement for frequent repairs

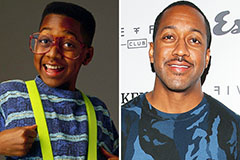

Jaleel White Then & Now!

Jaleel White Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Lucy Lawless Then & Now!

Lucy Lawless Then & Now!